Industrial and high volume customers that produce a large amount of refuse, both trash and recycling, may benefit from a compacting unit. Compactors are designed to compress solid refuse to provide disposal options for industrial businesses that generate an abundance of refuse, while maintaining an attractive aesthetic.

Compactors are a cost saving solution for businesses that have large waste or recycling streams. Most compacting units have a 4 to 1 compaction ratio. Meaning for every 4 truckloads of loose waste taken to the landfill, the same quantity of compacted waste would only require 1 trip. This means it will reduce the amount of hauls needed.

In addition to the cost savings, compactors discourage dumpster divers and scavenging, prevent illegal dumping, promote cleanliness in the workplace, and reduce pest problems.

We install, lease, and service industrial compactors and balers at many locations within Cedar Valley and the surrounding communities.

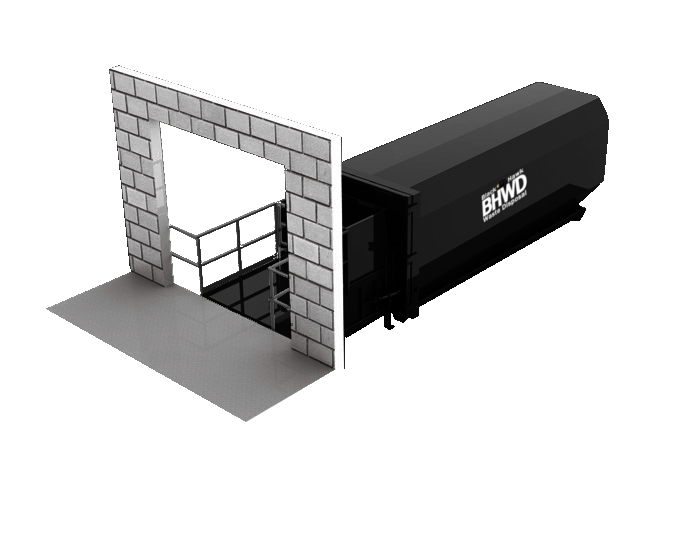

Stationary Compactors

Stationary compactors are a two-part unit designed to handle dry waste such as standard refuse, paper, cardboard, plastic, clothing, wood, bottles, aluminum and more.

The compacting unit is anchored to the ground and set in a permanent position. The box that holds the compacted material (receiver box) is unhooked, pulled away, tarped, and taken to the disposal site to be emptied. The compacting unit is left onsite.

Stationary Unit benefits:

- Larger unit options compared to self-contained units

- Hopper opening is larger for bulkier items like pallets or combo boxes

- Compacting unit is stationary so the box is set down in the same spot every time

Stationary Units are ideal for:

- Cardboard or Recycling refuse

- Retail, department stores, and warehouses

- Shopping Centers

- Chain Stores

- Offices

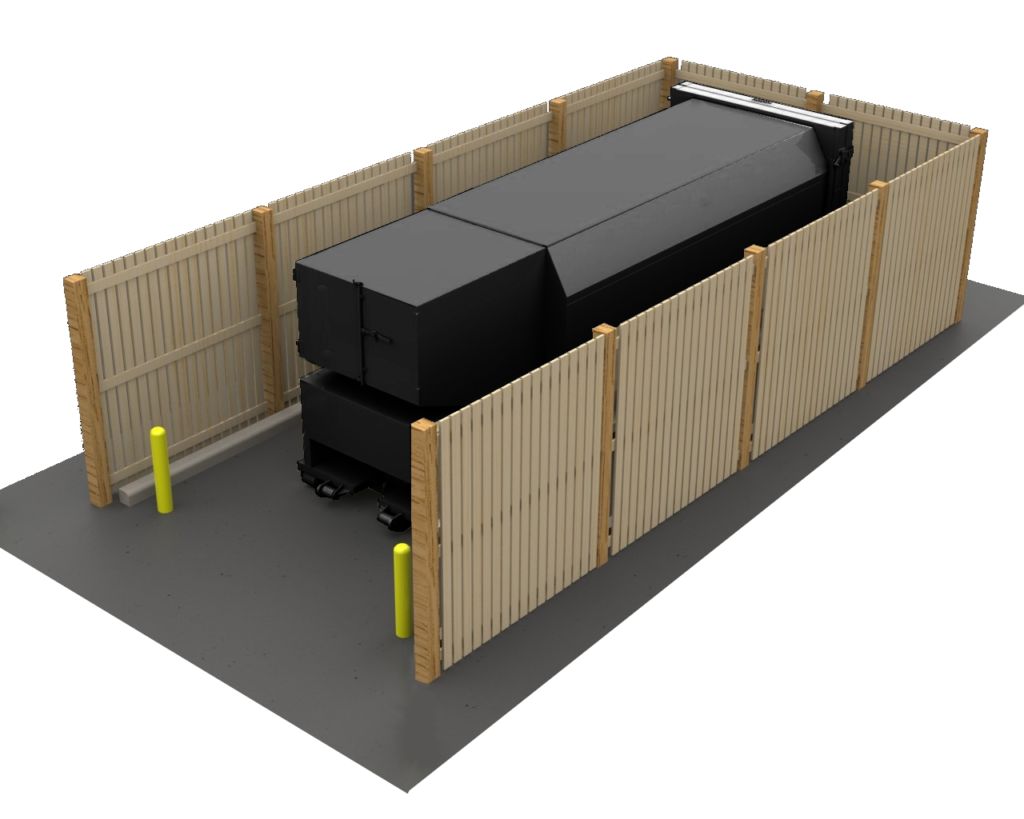

Self Contained Compactors

Self contained compactors are stand-alone one part unit designed to handle, in addition to standard refuse, food waste, medical waste, and other ‘non-standard refuse’ that may be odorous, wet, or hazardous.

The compactor in a self-contained unit is permanently attached. When a unit is emptied, the entire system is taken from the location.

The unit is loaded onto the back of the truck and transported to the disposal site. Once there, the unit has to be turned around before it can be emptied.

Self Contained Unit benefits:

- No cleanup when the unit is picked up

- Odor control

- Prevents refuse from being blown by the wind

- Smaller unit (lengthwise)

Self Contained Units are ideal for:

- Grocery Stores and Supermarkets

- Restaurants

- Hospitals

- Nursing Homes

- Industrial Plants / Packing Plants

- Food Courts

- Casinos

- Hotels/Motels

- Any other location with non-standard refuse

There are several options for compactor units to make them safe and convenient for every location.

Balers

Industrial balers, or bailing machines, are large equipment used to compress material, usually recyclable material, into small manageable bales for shipment and disposal. Bales are advantageous for storage due to their dense but small size. They are easier to handle, requiring only a forklift.

There are two main types of industrial balers, vertical and horizontal. Balers use hydraulics systems to compress the materials into rectangle squares of product.

Once a location has a bulk quantity of bales produced. A transportation or recycling company is scheduled to remove these bales, either at cost to the company or for a payback. This depends on the type of material and quality of bales.